Fast delivery within 72 Hours

Subwoofer Boxes

Mow Packaging introduces its high-quality Subwoofer Boxes designed specifically for the protection and transportation of subwoofers. These sturdy boxes provide a reliable way to store, ship, and display your subwoofers, ensuring they arrive at their destination in perfect condition. Mow Packaging's Subwoofer Boxes are engineered to provide a snug and secure fit, preventing movement and damage during transit. Available in a range of materials, including cardboard, kraft, and rigid containers, our Subwoofer Boxes cater to different needs and preferences. We also offer customization options, allowing you to add your brand's logo, colors, and message to create a personalized packaging solution. Whether you're a musician, sound engineer, or audio enthusiast, Mow Packaging's Subwoofer Boxes provide the perfect solution for protecting your valuable subwoofers. With our Subwoofer Boxes, you can trust that your subwoofers will be safely stored and transported, allowing you to focus on creating great music and unforgettable experiences. At Mow Packaging, we're committed to delivering high-quality packaging solutions that meet the unique needs of our customers. Contact us today to learn more about our Subwoofer Boxes and how we can help you keep your subwoofers protected and secure.

Read More...Warning: Undefined variable $text in /home/user_1/web/mowpackaging.com/public_html/wp-content/themes/woodmart/functions.php on line 1485

Shipping & Delivery

-

Standard:

Free Shipping

-

Express

Free Shipping

-

Expedite

Free Shipping

-

Free 30-Day returns

Specification

| Type | Specifications |

|---|---|

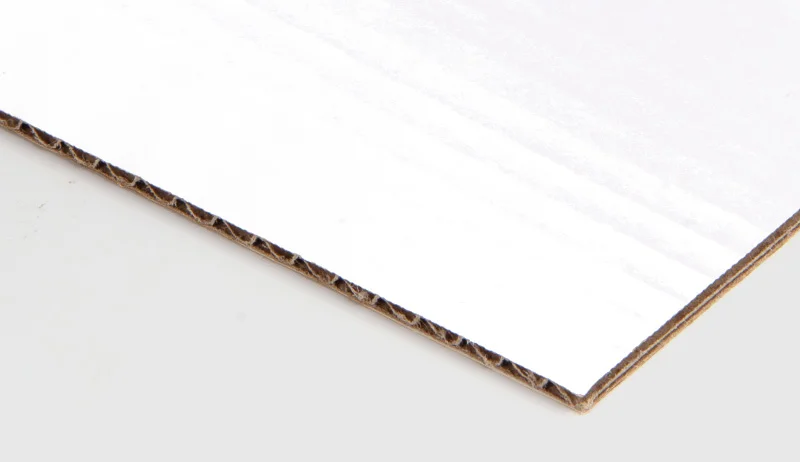

| Dimensions | All Custom Sizes & Shapes |

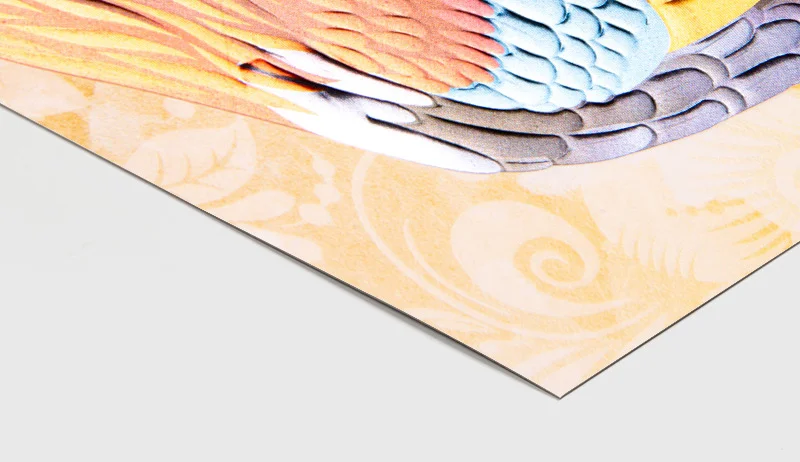

| Printing | CMYK, PMS, No Printing |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Quantities | 100 – 500,000 |

| Coating | Gloss, Matte, Spot UV |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

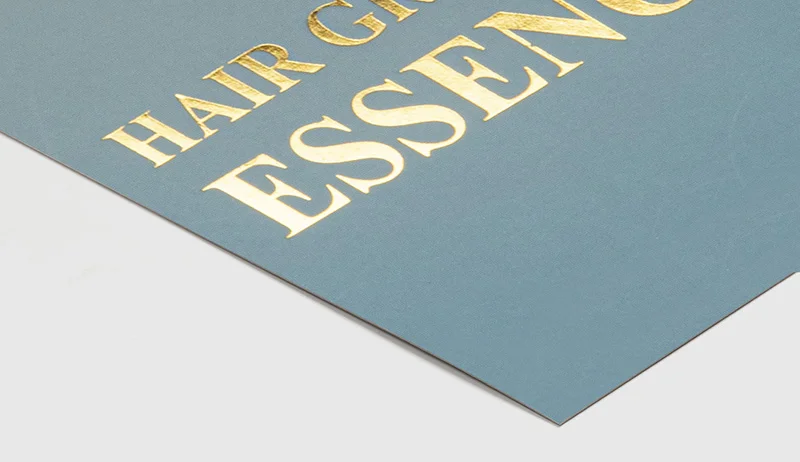

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turn Around Time | 4-6 Business Days, Rush |

Description

Subwoofer Boxes

At Mow Packaging, we understand the importance of protecting your valuable subwoofers during shipping and storage. That’s why we’ve created a range of Subwoofer Boxes designed to meet the unique needs of audio equipment manufacturers and retailers. Our packaging solutions are tailored to ensure your products arrive at their destination in perfect condition, while also providing a professional and cohesive brand image.

Features

Our Subwoofer Boxes are built to last, with a focus on durability and sustainability. Here are some of the key features that set our products apart:

Size Options

Our Subwoofer Boxes come in a range of sizes to accommodate subwoofers of all shapes and sizes. Whether you need a custom-made box or a standard size, we have you covered. Our sizes range from small to extra-large, so you can find the perfect fit for your product.

Printing Options

We understand the importance of branding, which is why we offer a range of printing options to help you create a professional and cohesive brand image. From simple text to complex logos, our printing services are designed to help you stand out in a crowded market.

Finishing Options

Our Subwoofer Boxes are finished with a range of options to suit your needs. From a simple crease and fold to a fully finished box with a cardboard or plastic insert, we can create a packaging solution that meets your exact requirements.

Benefits

So, what are the benefits of using our Subwoofer Boxes? Here are just a few:

- Protection: Our boxes are designed to protect your subwoofers during shipping and storage.

- Branding: Our printing services allow you to create a professional and cohesive brand image.

- Sustainability: Our eco-friendly packaging solutions help reduce waste and minimize environmental impact.

- Customization: Our custom-made boxes are tailored to your specific needs, ensuring a perfect fit for your product.

- Cost-Effective: Our packaging solutions are designed to be cost-effective, without compromising on quality.

Customization

At Mow Packaging, we understand the importance of customization. That’s why we offer a range of customization options to help you create a packaging solution that meets your exact needs. From size to material, printing to finishing, we can create a Subwoofer Box that is tailored to your specific requirements.

Material Options:

Kraft paper: A premium, eco-friendly option that is ideal for luxury brands.

Cardboard: A sturdy, affordable option that is perfect for budget-conscious manufacturers.

Rigid boxes: A robust, high-end option that is designed for premium products.

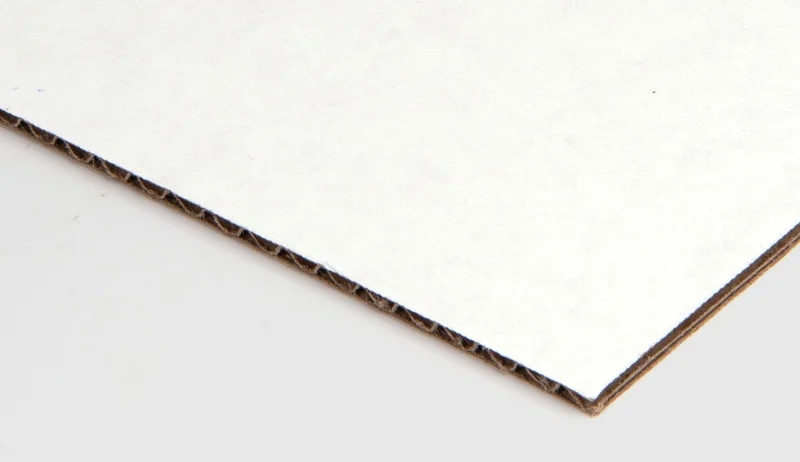

Corrugated boxes: A lightweight, easy-to-assemble option that is ideal for e-commerce manufacturers.

Use Cases

Our Subwoofer Boxes are designed for a range of uses, including:

Gifting: Our boxes are perfect for gifting subwoofers to customers or clients.

Branding: Our printing services are designed to help you create a professional and cohesive brand image.

Retail display: Our boxes are designed to display subwoofers in-store, helping to drive sales and increase brand awareness.

Protection: Our boxes are designed to protect subwoofers during shipping and storage, reducing the risk of damage and return.

Shipping: Our boxes are perfect for shipping subwoofers to customers, providing a secure and professional solution.

Why Choose Us

At Mow Packaging, we’re committed to providing you with the best possible packaging solutions. Here are just a few reasons why you should choose us:

- We’re a trusted brand: We’ve been serving the packaging industry for years, and we’re known for our reliability and expertise.

- We’re eco-focused: We’re committed to sustainability, and we’re constantly looking for ways to reduce our environmental impact.

- We’re experts: Our team of packaging experts are dedicated to providing you with the best possible solutions, tailored to your specific needs.

- We’re fast: We understand the importance of speed, and we’re committed to delivering your packaging solutions quickly and efficiently.

Question and Answers

Q: What materials do you use for your Subwoofer Boxes?

A: Our Subwoofer Boxes are made from a range of materials, including kraft paper, cardboard, rigid boxes, and corrugated boxes. We offer eco-friendly options such as kraft paper and corrugated boxes, which are perfect for luxury brands and environmentally-conscious manufacturers.

Q: Can I customize the size of my Subwoofer Box?

A: Yes, you can customize the size of your Subwoofer Box to fit your specific needs. We offer a range of sizes, from small to extra-large, and our custom-made boxes are tailored to your exact requirements.

Q: Do you offer printing services for my Subwoofer Box?

A: Yes, we offer a range of printing services, including simple text to complex logos. Our printing services are designed to help you create a professional and cohesive brand image.

Q: Are your Subwoofer Boxes durable and secure?

A: Yes, our Subwoofer Boxes are designed to be durable and secure. We use high-quality materials and construction methods to ensure that your products are protected during shipping and storage.

Q: Do you offer a guarantee or warranty for your Subwoofer Boxes?

A: Yes, we offer a satisfaction guarantee for all of our products. If you’re not satisfied with your Subwoofer Box, we’ll work with you to resolve the issue and provide a replacement or refund.

Q: Can I order a sample or prototype of my Subwoofer Box?

A: Yes, we offer a sample and prototype service for all of our products. This allows you to test and refine your packaging solution before placing a large order.

Q: How long does shipping take for your Subwoofer Boxes?

A: Our shipping times vary depending on your location and the size of your order. We offer expedited shipping options for urgent orders, and we’ll work with you to ensure that your products arrive quickly and efficiently.

Q: Do you have any certifications or accreditations for your Subwoofer Boxes?

A: Yes, we have several certifications and accreditations for our products and services. We’re committed to upholding the highest standards of quality and sustainability, and we’re proud to be recognized by industry organizations and regulatory bodies.

Customer Reviews

Choose Your Box

Start by browsing our extensive range of box styles and designs. Whether you're in the market for something simple and classic or intricate and bespoke, we've got a multitude of options to suit your needs.

Customize the Design

Once you've chosen a box style, it's time to make it uniquely yours. Upload your design or collaborate with our in-house design team to craft a packaging solution that resonates with your brand's aesthetic and vision.

Select Materials and Finishes

Our platform allows you to pick from a variety of materials, be it eco-friendly options, premium finishes, or durable structures. Enhance the tactile experience with finishes like matte, gloss, embossing, or specialty textures.

Review and Approve

Before we move to production, we'll send you a digital proof or a physical sample upon request. This ensures you're 100% satisfied with the design and materials chosen. Review, make any necessary changes, and give us the green light when you're ready.

Production Begins

Once you've approved the design, our team gets to work. With state-of-the-art machinery and a dedicated workforce, we ensure that each box is crafted to perfection, adhering to the highest quality standards.

Shipment and Delivery

With our efficient logistics network, we guarantee timely deliveries. As your boxes are packed and prepared for shipment, we'll provide tracking details to keep you informed every step of the way. Sit back and wait for your premium packaging to arrive at your doorstep./p>

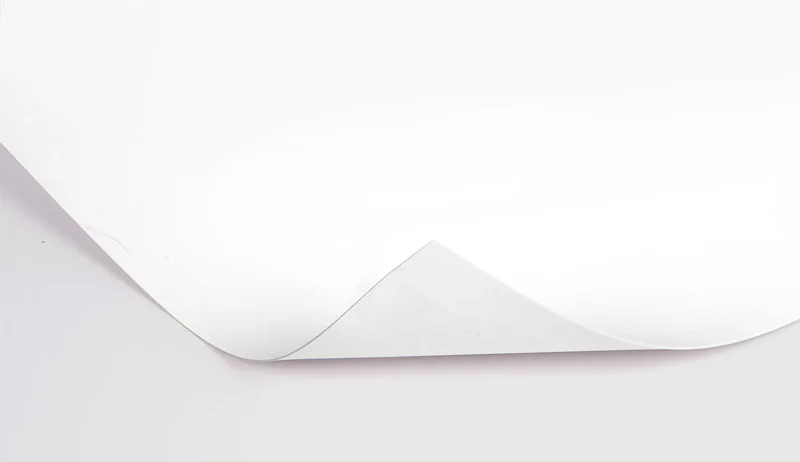

SBS C1S

Premium-grade bleached white paperboard coated on one side for high-quality printing and finishes.

SBS C2S

Premium-grade bleached white paperboard coated on two sides for high-quality printing and finishes.

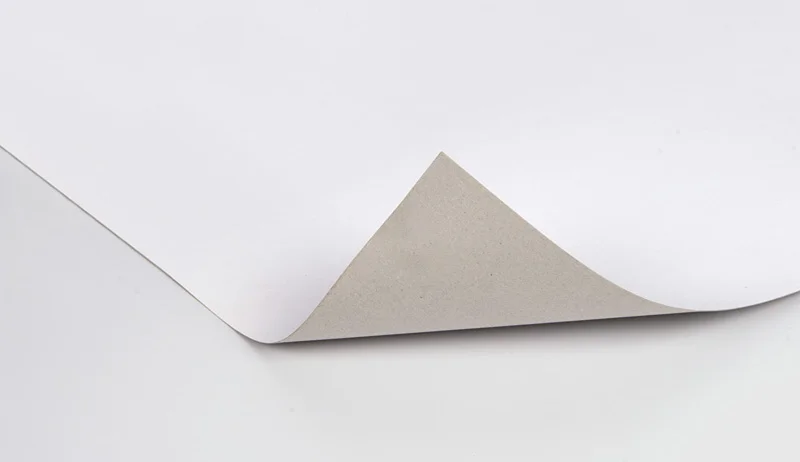

CCNB

Duplex paperboard made from 90% recycled paper pulp with a white surface for high-quality printing.

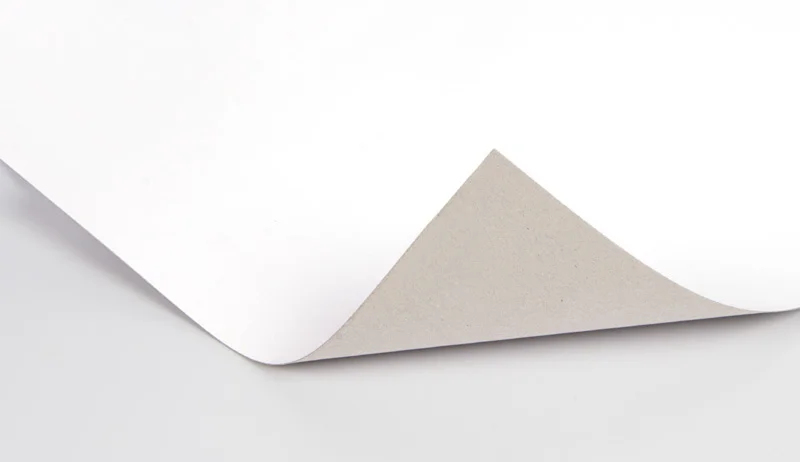

Fully Recycled CCNB

Duplex paperboard coated on one side and made from 90% recycled paper pulp.

Natural Kraft Board

Uncoated and unbleached kraft linerboard made from a mixture of virgin and recycled paper pulp.

Oyster White Board

Coated, textured linerboard featuring an off-white surface for high-quality printing.

Kemi White Board

Coated, semi-gloss linerboard that features a brilliant white and smooth surface for high-quality printing.

Bleached White Board

Bleached white board with a brilliant white finish for high-quality vibrant printing.

Aqueous Coating

Clear, fast-drying, water-based, and eco-friendly coating. Available in gloss or matte finish.

UV Coating

Fast-drying coating cured with ultraviolet light. Available in gloss or matte finish.

Spot Gloss UV

UV coating that is applied to a specified area and cured using ultraviolet light.

Soft Touch Coating

Soft to the touch coating that creates a velvety texture for a more tactile appeal.

Varnish

Clear coating applied using the CMYK printing method. Available in gloss, satin, or matte.

Lamination

Laminated protective film that adheres to the surface of packaging materials to maximize durability.

Anti-scratch Lamination

Laminated BOPP film that is scratch, scuff, and fingerprint resistant. Cost-effective option.

Soft Touch / Silk Lamination

Soft to the touch lamination similar to peach skin. Available in a satin or matte finish.

Hot Foil Stamping

Form of relief printing in which foil is transferred to a surface at high temperatures.

Cold Foil Printing

Form of relief printing in which foil is transferred to a surface by pressing onto UV curable adhesives.

Blind Embossing

Form of relief printing in which dies is pressed on the back of the material to form a raised motif.

Blind Debossing

Form of relief printing in which dies is pressed on the front of the material to form a raised motif.

Registered Embossing

Form of relief printing in which a die is pressed on the back of the material to form a raised motif.

Combination Embossing

Combination between embossing and foil stamping. It creates a 3D motif that features a foil finish.

Window Patching

Die-cut shape is layered with plastic film to feature a window showcasing the product inside.

Reviews

Clear filtersThere are no reviews yet.